Steel floating dome roof on top of the digester with the biogas from the digestion process being contained under the digester roof usually of mild steel which could rise or fall depending on gas production and demand much as the old town gas gas holders used to rise and fall with the passage of night and day.

Floating roof gas holder.

Floating gas holders can be made of steel fiberglass or a flexible fabric.

A separate tank may be used with a floating gas holder for the storage of the digestate and also storage of the raw biogas.

Floating gas holders can be made of steel fiberglass or a flexible fabric.

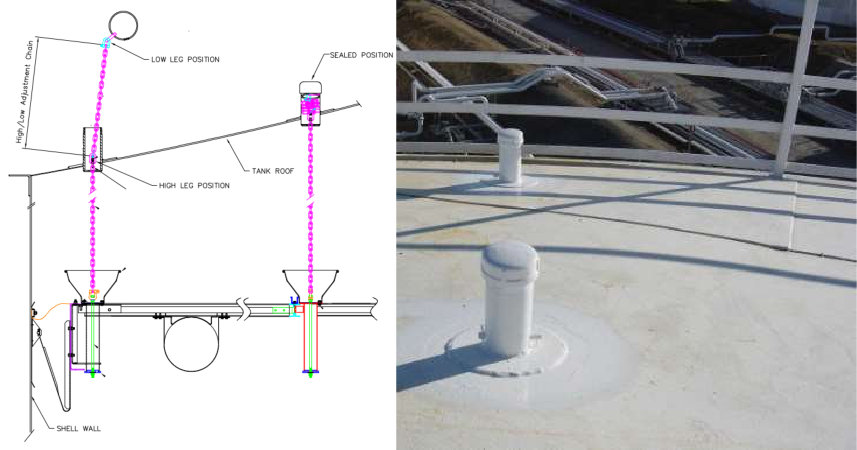

The gasholder cover which floats on digester gas rather than on the liquid surface is equipped with a skirt that extends below the liquid surface to contain gas.

The dome shaped gas holder is not fixed but is moveable and floats over the slurry present in the digester tank.

The floating gas holder type bio gas plant consists of a dome shaped gas holder made of steel for collecting bio gas.

A separate gas holder is necessary for fixed cover designs.

Another form of gas storage was later developed this was high pressure bullet tanks which stored gas at much higher pressure than those listed above.

This recommendation was based on capital and lifecycle costs maintenance and technical considerations.

One advantage of a digester with an integral gas storage component is the reduced capital cost of the system.

According to the report a floating roof also avoids the need to update the plant s environmental.

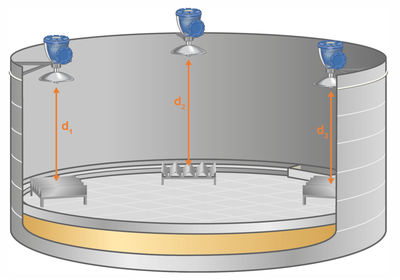

Accommodate gas storage as well as digester drawdown.

Most floating drum gas holders are made of 2 4 mm thick sheet steel with the sides made of thicker material than the top in order to compensate for the higher degree of corrosive attack.

Council discussed the recommendation of awarding the nearly 2 million request for proposal on a gas holder stainless steel floating roof.

A gas holder or gasometer is a large container in which natural gas or town gas is stored near atmospheric pressure at ambient temperatures the volume of the container follows the quantity of stored gas with pressure coming from the weight of a movable cap.

Floating covers rise and fall according to the volume of gas and sludge and their weight provides the gas pressure.

A major advantage of a digester with an integral gas storage component is the reduced capital cost of the system.

Due to this reason this biogas plant is called floating gas holder type biogas plant.

And x holders with a floating roof piston.

Structural stability is provided by l bar bracing that also serves to break up surface scum when the drum is rotated.

They have a perimeter rim skirt that provides the necessary gas to air seal which allows the storage of biogas.

Typical volumes for large gas holders are about 50 000 cubic metres 1 800 000 cu ft with 60 metres 200 ft diameter structures.